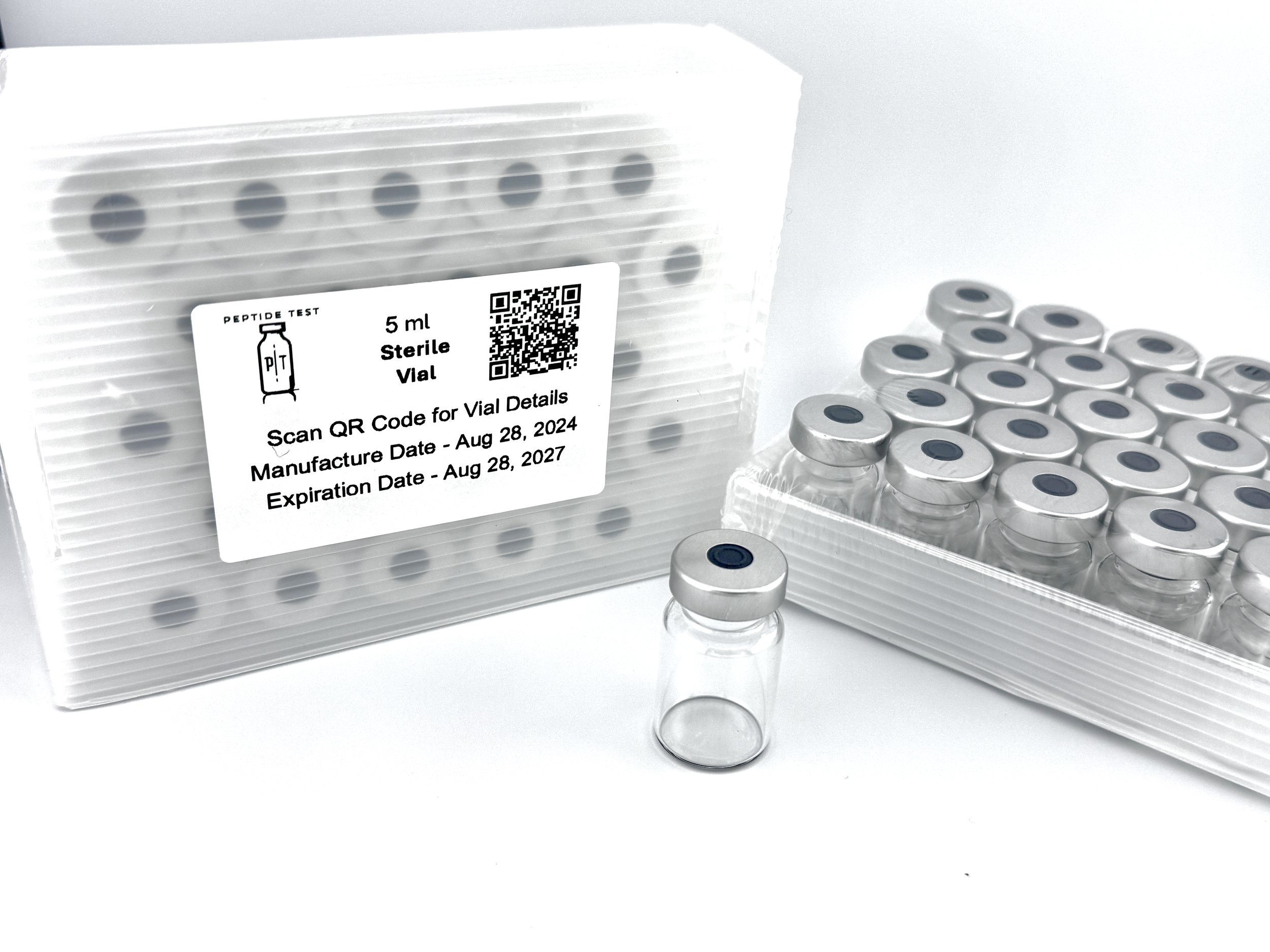

3 ml Sterile Vials - Exp 10/10/27

Volume: 2/3cc (2/3ml) 16x35mm

Cap diameter: 13mm

Color: Clear

USP <71> tested for sterility and endotoxins

Type I Glass United States Pharmacopeia (USP) <660>

cGMP FDA manufacturer

Chlorobutyl stopper with Teflon, no latex

Aseptically assembled in an ISO 5 (class 100) cleanroom

Type I glass vials, commonly used for injectable pharmaceuticals, are made from high-quality borosilicate glass. This material offers excellent chemical durability and thermal resistance, making it suitable for a wide range of pharmaceutical applications

Key Features:

• High Chemical Resistance: Ensures compatibility with a variety of pharmaceutical formulations.

• Thermal Stability: Suitable for processes like autoclaving and lyophilization.

• Regulatory Compliance: Meets stringent standards for pharmaceutical packaging, ensuring safety and efficacy.

Applications:

• Ideal for storing injectable drugs, vaccines, and other parenteral solutions.

• Suitable for both liquid and lyophilized (freeze-dried) products.

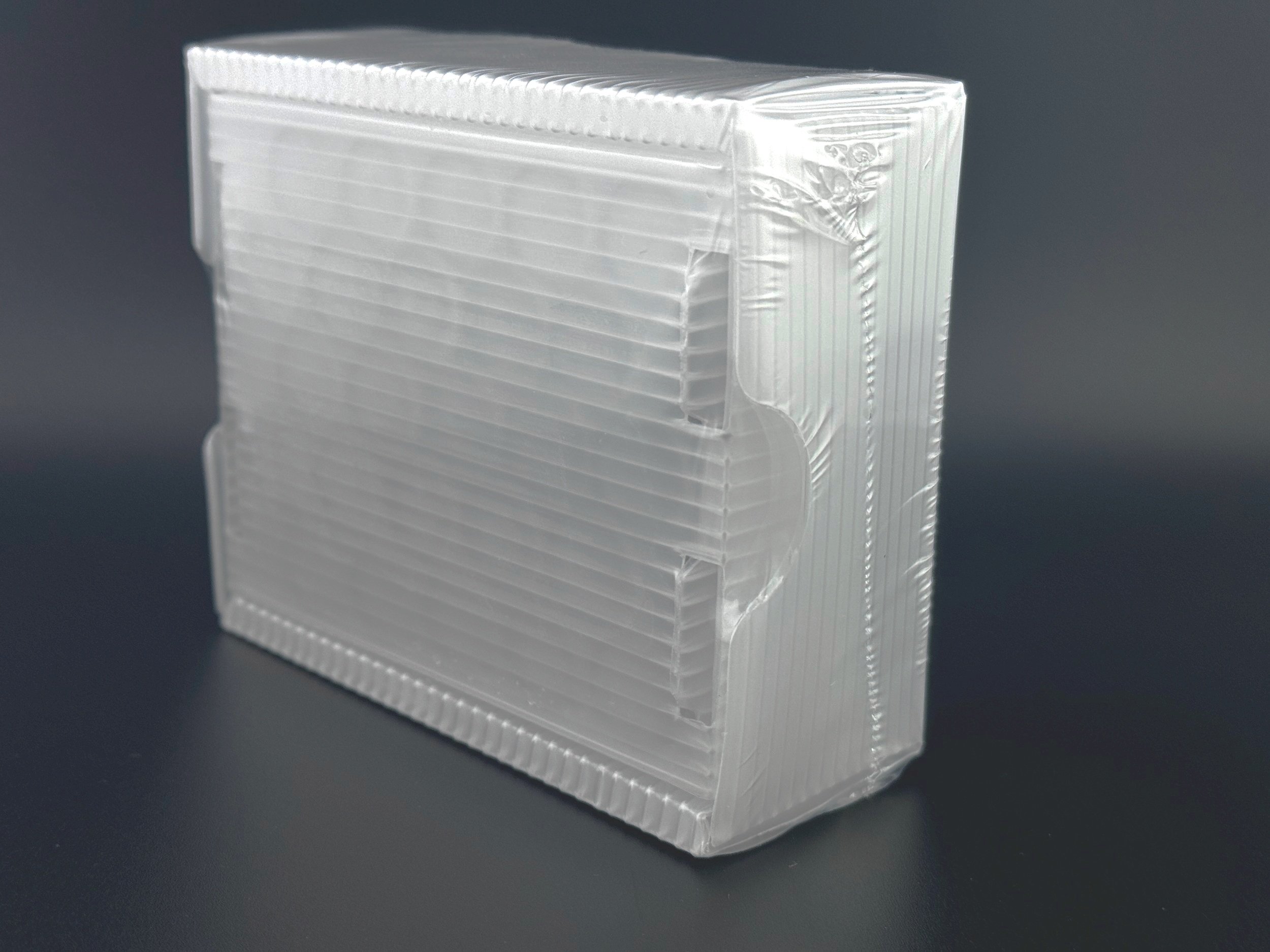

Packaging: Shrink-wrapped trays or sealed mylar pouches to minimize particulate contamination

Volume: 2/3cc (2/3ml) 16x35mm

Cap diameter: 13mm

Color: Clear

USP <71> tested for sterility and endotoxins

Type I Glass United States Pharmacopeia (USP) <660>

cGMP FDA manufacturer

Chlorobutyl stopper with Teflon, no latex

Aseptically assembled in an ISO 5 (class 100) cleanroom

Type I glass vials, commonly used for injectable pharmaceuticals, are made from high-quality borosilicate glass. This material offers excellent chemical durability and thermal resistance, making it suitable for a wide range of pharmaceutical applications

Key Features:

• High Chemical Resistance: Ensures compatibility with a variety of pharmaceutical formulations.

• Thermal Stability: Suitable for processes like autoclaving and lyophilization.

• Regulatory Compliance: Meets stringent standards for pharmaceutical packaging, ensuring safety and efficacy.

Applications:

• Ideal for storing injectable drugs, vaccines, and other parenteral solutions.

• Suitable for both liquid and lyophilized (freeze-dried) products.

Packaging: Shrink-wrapped trays or sealed mylar pouches to minimize particulate contamination

Volume: 2/3cc (2/3ml) 16x35mm

Cap diameter: 13mm

Color: Clear

USP <71> tested for sterility and endotoxins

Type I Glass United States Pharmacopeia (USP) <660>

cGMP FDA manufacturer

Chlorobutyl stopper with Teflon, no latex

Aseptically assembled in an ISO 5 (class 100) cleanroom

Type I glass vials, commonly used for injectable pharmaceuticals, are made from high-quality borosilicate glass. This material offers excellent chemical durability and thermal resistance, making it suitable for a wide range of pharmaceutical applications

Key Features:

• High Chemical Resistance: Ensures compatibility with a variety of pharmaceutical formulations.

• Thermal Stability: Suitable for processes like autoclaving and lyophilization.

• Regulatory Compliance: Meets stringent standards for pharmaceutical packaging, ensuring safety and efficacy.

Applications:

• Ideal for storing injectable drugs, vaccines, and other parenteral solutions.

• Suitable for both liquid and lyophilized (freeze-dried) products.

Packaging: Shrink-wrapped trays or sealed mylar pouches to minimize particulate contamination